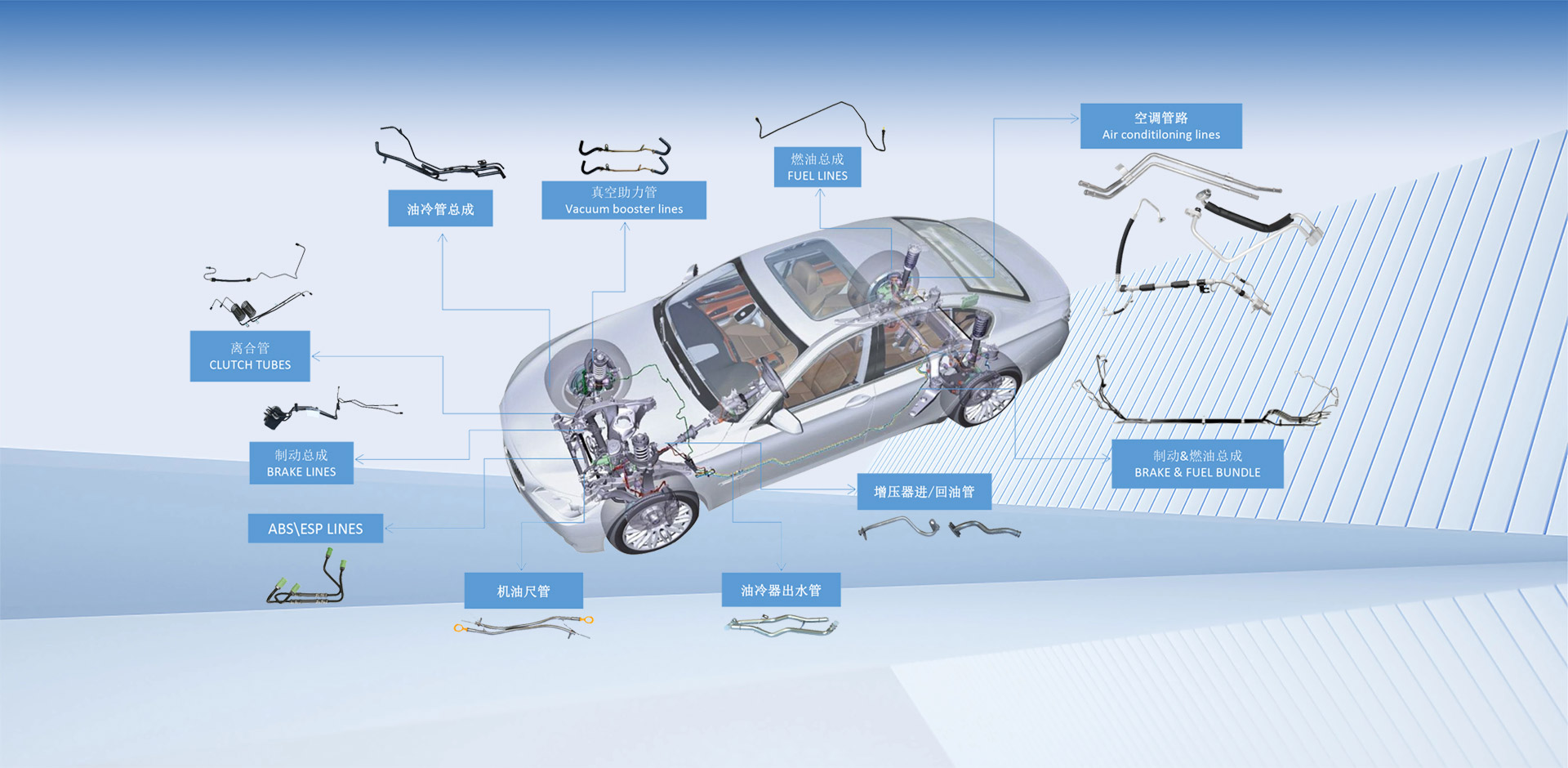

Focus on automotive pipeline system solutions | An industry benchmark enterprise with proven strength

Henan Skate Automobile Pipeline Co., Ltd. is located in Yuanyang, Henan Province, which lies on the fertile and talented Yubei Plain. Facing the provincial capital Zhengzhou across the river, it has long been known as the "back garden of Zhengzhou". With the Beijing-Guangzhou Railway, Beijing-Zhuhai Expressway, National Highway 107, and Provincial Highway 310 running through its territory, it is only 50 minutes' drive from Zhengzhou International Airport and Zhengzhou Railway Station, enjoying smooth logistics and convenient transportation.Founded in 2001, the company has grown into an automotive pipeline manufacturer integrating scientific research, development, production, sales and service after decades of technical accumulation and innovative development. The company has a registered capital of 10 million yuan, a total floor area of 35,000 square meters, and a total fixed asset value of 60 million yuan. It mainly manufactures pipelines for vehicle brake systems, power systems and thermal management systems, with an annual production capacity of 3 million sets. Currently, its major customers include Changan Automobile, Dongfeng Automobile, Chery Automobile, SAIC Maxus, Seres Automobile, Yutong Bus, Zhengzhou Nissan, Deepal Automobile, Avatr Automobile, Voyah Automobile, and Hezhong Automobile, etc.Since its establishment, the company has always adhered to the people-oriented principle, with high starting point investment and standardized production. It obtained ISO9000 quality management system certification from China Quality Certification Center (CQC) in 2002, ISO/TS16949:2002 international quality management system certification in 2007, and the new version of IATF16949:2016 international quality management system certification in 2018. In 2016, it passed the ASES audit of Nissan Motor, as well as ISO14001:2015 environmental management system certification and GB/T45001:2018 occupational health and safety management system certification. It has been awarded honors such as "National High-Tech Enterprise", "Henan Provincial Engineering Technology Research Center for Automobile Pipeline Systems", "Henan Provincial Specialized, Refined, Characteristic and Novel Small and Medium-Sized Enterprise", "Henan Provincial Science and Technology-Oriented Small and Medium-Sized Enterprise", "Industry-University-Research Cooperation Base of Henan Institute of Technology", and "Henan Famous Trademark".The company boasts a high-quality workforce and advanced production, experiment and testing equipment. It currently has 280 employees, including 32 full-time personnel for technical research and development as well as quality assurance, 38 management personnel, and 210 direct production personnel. The main production equipment includes internationally advanced automatic cutting machines, automatic heading machines, CNC pipe bending machines, and pass-through heat-shrinking furnaces. The experimental and testing equipment includes high-precision testing instruments such as pressure leakage testing machines, burst testing machines, salt spray testing machines, tensile testing machines, full-spectrum direct-reading spectrometers, coordinate measuring machines, image measuring instruments, and profilometers, along with a complete set of cleanliness testing equipment and clean rooms. Every product of the company, from raw materials to finished products, is governed by the quality management system, adhering to lean production and refined management.Looking forward to the future, all members of Skate will, as always, uphold the corporate spirit of "integrity, passion and perseverance", walk hand in hand with you and create brilliance together!